eddy current thickness measurement principle|eddy current vs paut : discounter The eddy current test method •Control circuit passes an AC through an induction core ‒Creates an alternating magnetic field, generating eddy currents in an electrically conductive material . WEB20182 h 34 min. Ficção científicaFantasiaSuper-heróisAção e aventura. OBTER DISNEY+. Com o poderoso Thanos a preparar-se para atacar o universo, os Vingadores e os .

{plog:ftitle_list}

Resultado da Gorda velha (3,101 results) Report. Related searches viejas gordas coroa gorda sogra velhas gordas black light skin bbw under skirt may bay vn có tiéng gorda hairy thick missionary negras peludas gordas masturbandose velha gozando na boca coroa velha gordas culonas mexicana gorda .

Magnetic pull-off gages consist of a permanent magnet, a calibrated spring and a graduated scale. The attractive force between the permanent magnet and the steel pulls the magnet toward the steel. The magnitude of this attractive force is related to the . See moreCoating and plating thickness measurements are sensitive to surface roughness, substrate curvature, alloy content and, in the . See more What are Eddy Current Paint Thickness Gauges? Eddy current techniques are used to nondestructively measure the thickness of nonconductive coatings on nonferrous metal substrates. A coil of fine wire . 2.1 Thickness Measurements with Eddy Current Technique. The typical basic operating principle of eddy currents is very simple. An excitation coil induces eddy currents in .

The eddy current test method •Control circuit passes an AC through an induction core ‒Creates an alternating magnetic field, generating eddy currents in an electrically conductive material .In addition to crack detection in metal sheets and tubing, eddy current testing can be used for certain metal thickness measurements such as identifying corrosion under aircraft skin, measuring conductivity and monitoring the effects of heat .

Thickness Measurements of Nonconducting Coatings on Conductive Materials. The thickness of nonmetallic coatings on metal substrates can be determined simply from the effect of liftoff on .The typical basic operating principle of eddy currents is very simple. An excitation coil induces eddy currents in the test sample while magnetic sensors or sensing coils measure the .The eddy-current principle enables the non-destructive coating thickness measurement on non-magnetic metal substrates eg. aluminium, aluminium alloys, lead, bronze, copper, brass, zinc, die-cast zinc, tin. The Eddy current .With the amplitude-sensitive eddy current method, you can measure the thickness of coating materials on electrically conductive but non-magnetic materials. In principle, this involves non-ferrous metals. The coating .

Eddy current testing and more recently eddy current array (ECA) is one of the standards of thickness measurement because it can be used for nonconductive coatings on conductive-base materials. By inducing a magnetic field, ECA can .Eddy current testing is a non-destructive testing (NDT) inspection method used for a variety of purposes, including for flaw detection, material and coating thickness measurements, material identification and establishing the heat .The PosiTector 6000 is a rugged, fully electronic coating thickness gauges use magnetic and eddy current principles to measure coating thickness on ALL metals, accurately and quickly . The coating thickness measurement range .Eddy current testing is typically used for nonconductive coatings, and ultrasonic for most standard wall thickness testing measurements. In many large-scale manufacturing efforts, using the right equipment for the job is the only way to .

In this article, Mikrometry will show you the basic working principle for eddy current thickness testing and magnetic thickness measurement. Click to know more now! . The coating thickness meter of magnetic thickness measurement eddy current thickness measurement is also called iron-aluminium dual-purpose coating thickness meter. 2. Coating .

who does eddy current testing

high frequency eddy current inspection

Due to its advantage of high sensitivity and strong adaptability to the specimen, eddy current testing is widely used for the thickness measurement, liquid level measurement, and defect detection .With the amplitude-sensitive eddy current method, you can measure the thickness of coating materials on electrically conductive but non-magnetic materials. In principle, this involves non-ferrous metals. The coating material itself must show .

Fairly precise measurements can be made with a standard eddy current flaw detector and a calibration specimen. The probe is nulled in air and the direction of the lift-off signal is established. The location of the signal is marked on the screen as the probe is placed on the calibration specimen in areas of decreasing coating thickness.

The eddy-current principle enables the non-destructive coating thickness measurement on non-magnetic metal substrates eg. aluminium, aluminium alloys, lead, bronze, copper, brass, zinc, die-cast zinc, tin. The Eddy current principle is used in models marked with N or FN (N=Non-Ferrous), e.g. Surfix® easy I-FN. Eddy current testing (ECT) which is based on the principle of electromagnetic induction is regarded as an effective nondestructive testing method [].It can be used to detect surface [2, 3] and subsurface [4, 5] defects in conductive materials and measure thicknesses [6, 7] of metallic plates.It is well known that eddy current (EC) density is maximal on conductor . 2.1 Thickness Measurements with Eddy Current Technique. The typical basic operating principle of eddy currents is very simple. An excitation coil induces eddy currents in the test sample while magnetic sensors or sensing coils measure the reaction magnetic fields. The analysis of the reaction magnetic field allows defining the characteristics .

appropriate term. For the purposes of this chapter, Eddy Current, Eddy Current Inspection, and/ET will be used. 4.1.3 Inspection With Eddy Current.The eddy current inspection method is a highly capable, reliable inspection method. When used by a trained technician, it can be used to detect surface and some subsurface cracks, determine materialDry film thickness measurements can be used to evaluate a coating’s expected life, the product’s appearance and performance, and ensure compliance with a host of International Standards. . Electromagnetic induction is used for non-magnetic coatings on ferrous substrates such as steel, whilst the eddy current principle is used for non . The developed dual sensor is proven to be accurate to less than �1 Pm through experiments for three base metals with polyvinyl coatings of three different thickness. Keywords: Eddy-current, Capacitance, Coating thickness measurement 1 INTRODUCTION Thin films of about 10 ~ 100 Pm in thickness are usually coated over the surface of .

The Eddy Current Principle works as the Self-inductance. . and measure of flux in the transition and has a converse relative rate to the conductor's resistivity. This is the fundamental Eddy Current Principle. . T = thickness of a material. 2. .Digital Coating Thickness Gages for ALL Metal Substrates PosiTector 6000. The rugged, fully electronic PosiTector 6000 Coating Thickness Gage uses magnetic and eddy current principles to measure coating thickness on both ferrous .One of the major advantages of eddy current as an NDT tool is the variety of inspections and measurements that can be performed. In the proper circumstances, eddy currents can be used for: Crack detection; Material thickness measurements; Coating thickness measurements; Conductivity measurements for: Material identification; Heat damage detection

Eddy Current Coating Thickness Gauge. An eddy current coating thickness gauge is a type of gauge used to measure the thickness of coatings on non-ferrous (non-magnetic) substrates. It operates based on the . An eddy current is also called the Foucault current. Eddy currents are swirls of electric currents induced within conductors by a changing magnetic field within the conductor (self-inductance). Eddy current works on the principle of Faraday’s law of induction. The Eddy Current Principle works as the Self-inductance.The eddy current principle is used for non-conductive coatings on non-ferrous metals substrates. Elcometer offer a range of digital coating thickness gauges from the new Elcometer 456 - available with either integral or separate probes, the Elcometer 415 Paint and Powder Thickness Gauge, to the Elcometer 311 Automotive Refinishing Gauge.Learn how the phase sensitive eddy current principle ensures precise coating thickness measurement for metals and non-conductive materials. Ideal for reliable, non-destructive testing in various industries.

Pulsed Eddy Current technology evolves from Eddy Current principle • Non-contact technology • Promotes material-independent dimension measurement • Accurate measurements and unaffected by harsh environments e.g. fluids, steam and particles • Enables a sensor design without fragile parts and with superior long-term stability

For measurement using the Eddy current principle, we normally use a probe containing an air-core coil, without an iron core. A high-frequency alternating current flows through the coil. If the coil with its AC field is placed near a non-ferrous metal object, this creates an alternating current in the metal – a so-called eddy-current. Overview of magnetic and eddy current measurement principles. When it comes to coating thickness measurement, two commonly used principles are magnetic induction and eddy current.Let’s take a closer look at each of these principles: 1️⃣ Magnetic Induction: Magnetic induction is a widely employed method for measuring coating . Working principle of transient eddy current NDE. . The transient eddy current NDE measurements for thickness evaluation in conducting materials have been performed by using two sets of aluminum plates. The first set consists of six identical aluminum plates. The length, width and thickness of the each plate are 200 mm, 160 mm and 2 mm .The thickness of the surface coating has a great influence on their performance in the application of metal materials. Accurate measurement of the coating thickness is of great significance. In this paper, based on the eddy current thickness measurement principle, the information of coating thickness can be converted into the parallel resonance impedance as a reaction of .

The user wanted to measure the thickness of a thin conductive film for electric vehicle (EV) battery production. The step height, the difference between probe and roller and probe film height, was used to determine the film thickness. . Eddy Current Probes: Basic Operating Principles. Eddy current probes use an alternating AC current to .Eddy current sensors have been widely used in the field of micro- and nano-measurements. The detection circuit is a key part of eddy current sensors. In particular, the electrical parameters in the signal conversion circuit have an important effect on the measurement performance. It is necessary to study the effect of the electrical parameters on the measurement performance .

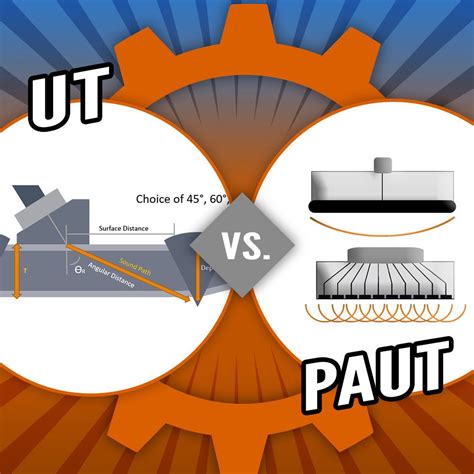

eddy current vs ultrasonic testing

test permeability

Resultado da 1 de fev. de 2024 · Com título original de “When Evil Lurks” (“Quando o Mal Espreita”, em tradução literal), a trama é dirigida por Demián Rugna e acompanha dois irmãos que encontram um homem possuído por um demônio, prestes a dar à luz ao mal que carrega, em uma aldeia remota.

eddy current thickness measurement principle|eddy current vs paut